Our waterjet cutting service gives you an opportunity to reduce production costs. High-precision guiding system and quality control system assure processing of complicated details, maximum speed and precision.

Waterjet cutting technology brings many advantages, some of which are:

- waterjet cutting does not heat the material, which is particularly useful for the steels which are suitable for heat treatment,

- waterjet cutting of tool steel and other metals in which exposure to high temperature can change the characteristics of the material,

- small cutting width allows for better utilization of raw materials,

- production of prototype parts is much simpler by using machine-guided waterjet cutting. Dimensions of parts can be entered into the control unit and the machine will precisely cut so programmed shape. That way of making prototype parts is much quicker and less expensive than the usual ways in which we first develop detailed plans that can then be submitted to operator who will make the part,

- the performance of the water-cutting is fully automated making it easy for mass production,

- water-cutting leaves no serrated or sharp edges which eliminates the need for additional treatment,

- waterjet cutting of all types of materials,

- waterjet cutting price is defined by the type of material, thickness and the required quality of cut

Our waterjet cutting machine can cut objects that have thickness from 0.5 to 120 (175) mm and maximum dimensions are 1510 x 3110mm.

Wide range of materials suitable for waterjet cutting includes:

- steels of all kinds

- hard materials

- copper

- aluminum

- glass

- polyvinyl mass

- vekaplan

- wood

- Styrofoam

- multilayer with layers of different hardness

- carbon

- etc …

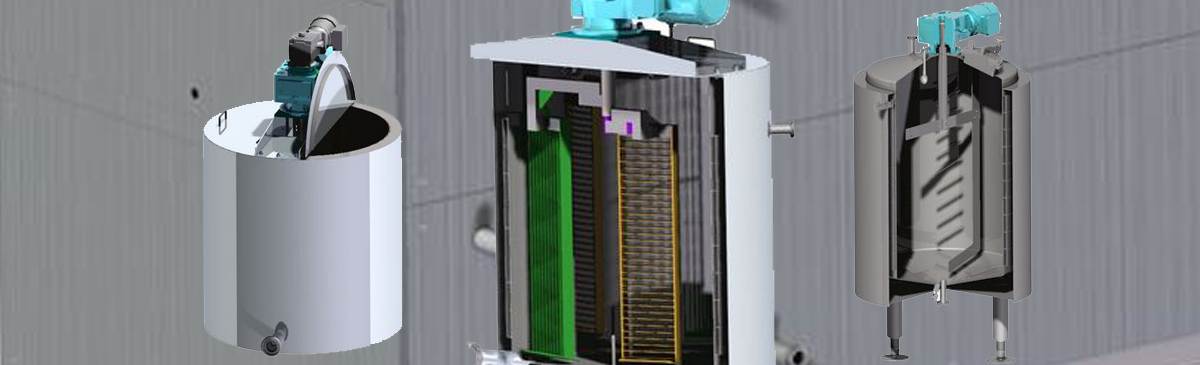

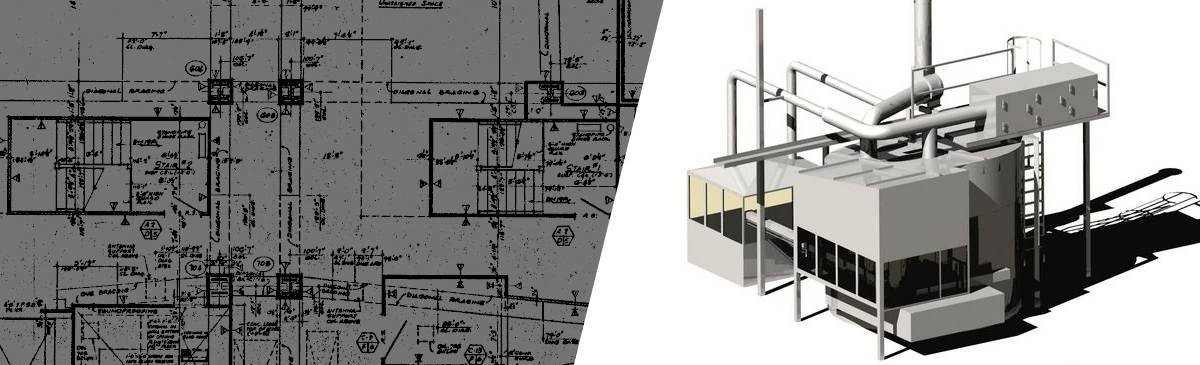

Some products derived from waterjet cutting